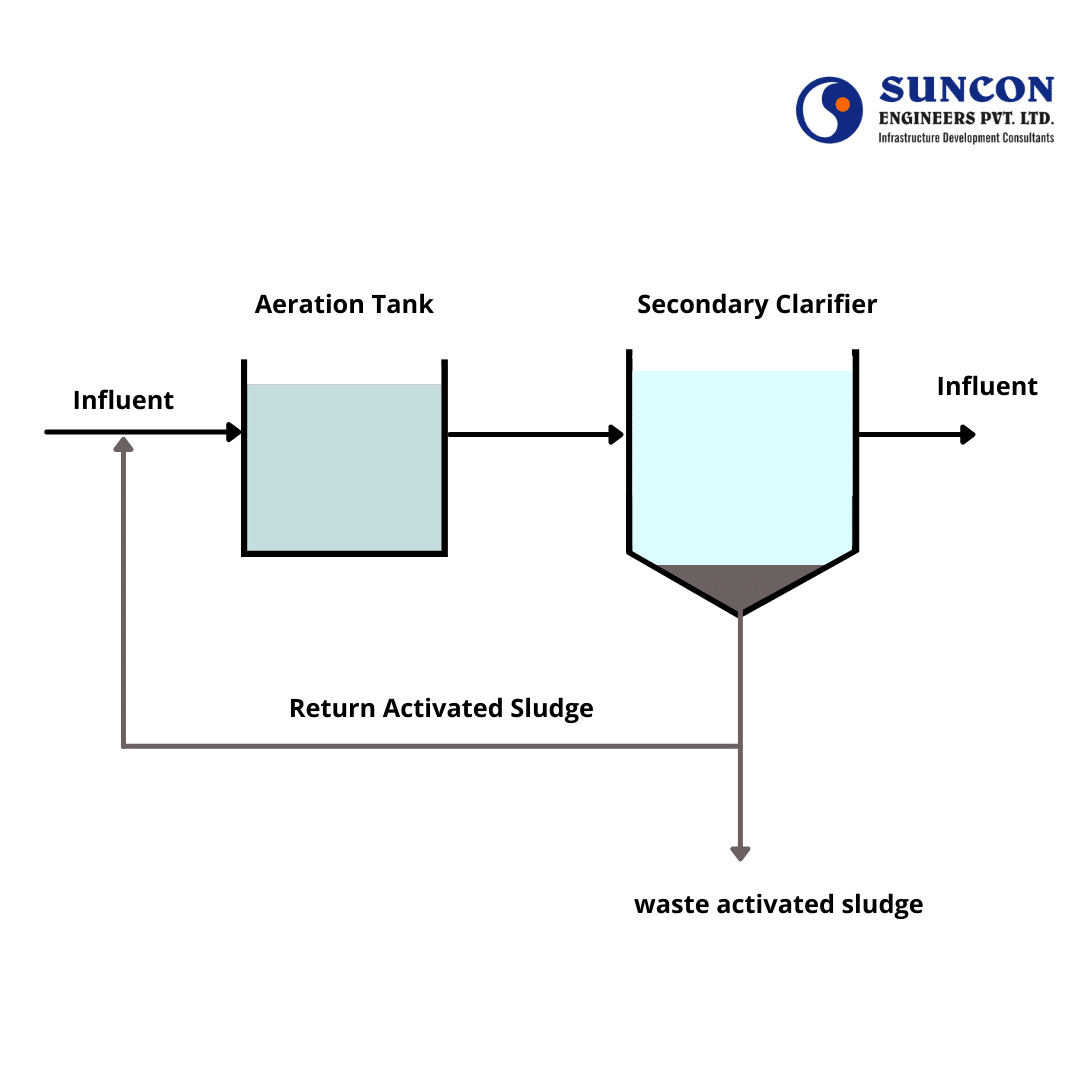

An Activated Sludge Process (ASP) system commonly includes an aeration tank and a secondary clarifier. The first is used for biological degradation and the other is used to separate sludge from the treated wastewater.

Steps:

1. Wastewater is mixed with air in the aeration tank and thus activate micro-organisms.

2. In secondary clarifier or settling tank, micro-organisms with their absorbed organic material settle.

3. Water is then transported to installations for disinfection or to other treatment units for purification.

4. The surplus micro-organisms can easily be channeled to any of our sludge treatment solutions where energy can be recovered from the biosolids. Thus this makes the energy cycle of this treatment plant run independently of fossil fuels.

Advantages:

●Cost-effective and good quality effluent

●Area requirement is less

●Freedom from fly and odor nuisance high degree of treatment

●Easily maintained mechanical work

●Self-sustaining system

In the coming articles, we will see other methodologies. Stay tuned!

Upcoming methods:

1. Moving Bed Bio-Reactor (M.B.B.R.) technology

2. Sequential Bed Reactors (SBR) technology.

3. Phytorid Technology.

4. IWT: integrated Wetland Technology.

5. Tiger Bio-Filter.