With the step-in movement in green and sustainable planet and increased use of energy due to globalisation and technology, world has taken a step towards generating energy specifically from the renewable resources than using non-renewable resources.

The increased demand in requirement of energy and the previous methods which are being used for generating energy has led to the depletion of major non-renewable sources which are used. A recent tragedy can be seen a few days back when government has declared that, the coal reserves which were used for energy generation has come to depletion in India. This if happened can going to adversely affect our lives and nature in the respective manner.

Such scenario being forecasted, the world forum is now focusing on generating electricity by the means of green – sustainable methods and the use of renewable resources. This will not only help in restoration of fossil fuels and non-renewable energy sources but also can be helpful in restoring nature and decarbonising the world. This will be a crucial step in the decarbonisation of the world.

Under the concept of the use of renewable energy (green sustainable energy), it is related to using wind energy, solar energy, tidal energy etc. for generation of energy, and use of such can be seen over from a few decades back. New innovations and upgrades in technology can be seen on daily basis in this sector.

We, are here to talk about some of such method, which is very innovative here in the field of energy generation using the wind energy. Before, we are all aware of the use of wind energy for energy generation by the means of windmills. Such huge windmills are been set on the cliffs and the valley areas, where we can observe the gush and breezes of wind at most speeds and highest flow rate. This wind gushes and forces blades of windmill to rotate due to their aerodynamic design. Dur to this rotation we can observe the conversion of kinetic energy into potential energy which further churns the generator shaft and here we get our energy. Now this concept is not new and I am sure everyone is well aware of the technology.

Now as per the modern-day studies in sustainable energy production, it is observed as the wind energy we observe here on land (on-shore) is comparatively very low as compared in seas and oceans (off-shore). This, led to an out of the box discovery and now it has been decided to plant such windmills off-shore to maximise the use of wind gush and generation of energy by the means of it.

Now the problem is to place such massive windmill stations on the sea. This can be done by constructing such mills on the ocean floor-bed or can be floating on the sea surface. But how can it be done was a serious question aroused?

The construction of windmills on the floor bed was not a seemingly feasible option. Hence it is now depended on the floating option only. The tall 120 m high tower and with a weight of thousand of tons, hoe its going to be floating of the sea surface?

The solution here was given by Archimedes 2,300 years ago: “a body totally or partially submerged in water experiences a vertical upward thrust equal to the weight of the water dislodged”. And the use of this principle has led to the construction of floating offshore wind platform (FOWP).

A floating offshore wind platform (FOWP), is the concrete, steel or hybrid substructure on which the wind turbine is installed, providing it with buoyancy and stability. Some call it a “floating foundation”, but this term is not correct because floating platforms are not founded on the seabed, but are anchored and fixed firmly.

Floating wind farms are made up of wind turbines that are placed on floating structures and stabilised by moorings and anchors, and by the way the design of the structure distributes the masses and weights. From there, the process is the usual one: the force of the wind turns the blades and the wind turbine converts the kinetic energy into electricity, which is transported by underwater cables to an offshore substation and from there to an onshore substation on the coast and finally to homes via the power lines.

In addition to floating, wind turbines must produce as much energy as possible, and to do this it is essential that they remain stable, minimising any movement and ensuring that they operate under optimum conditions. This is where the different types of floating platforms for wind turbines come into play, which we will review below.

Types of floating platforms for wind turbines

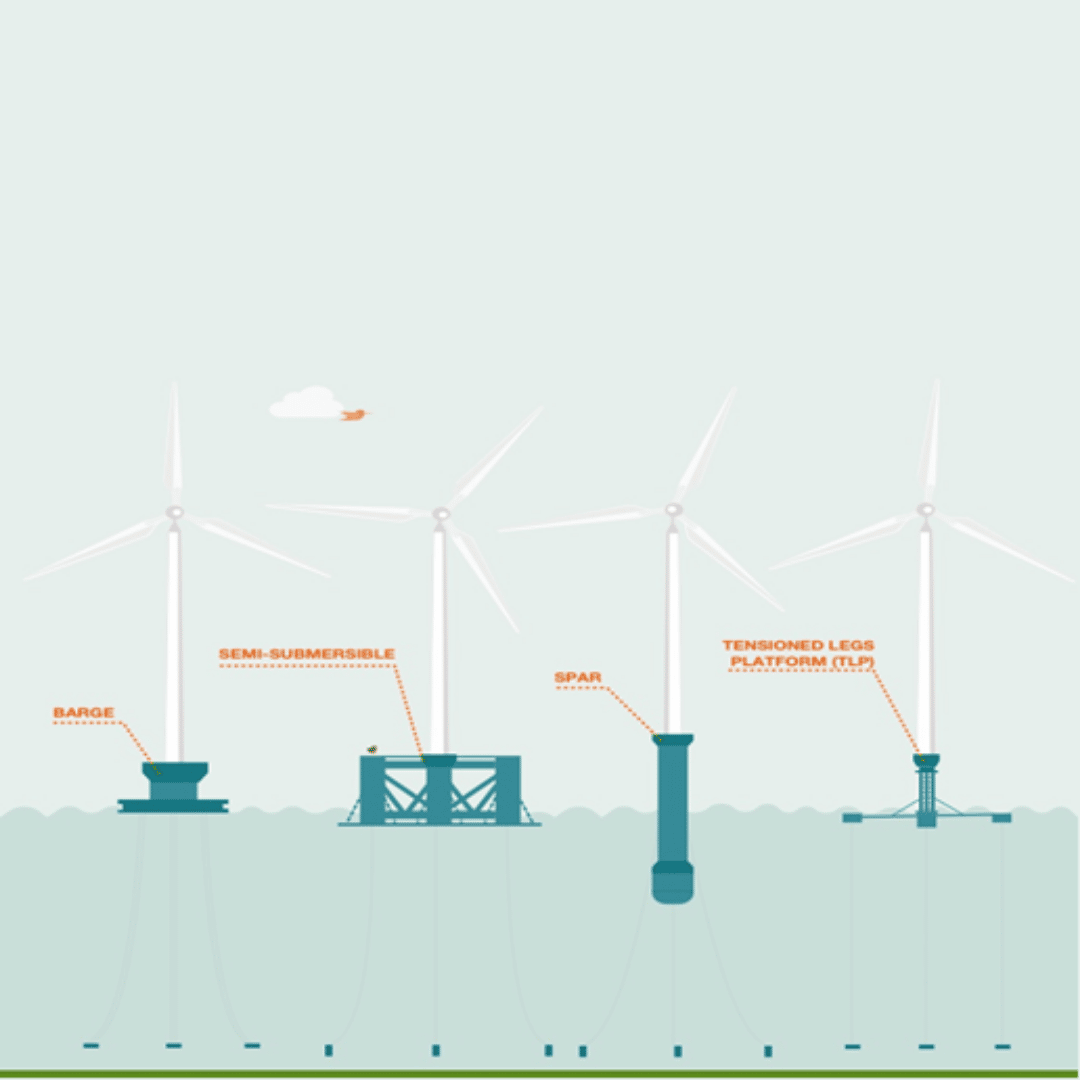

The various types of floating platforms and their choice totally depends on sea and seabed condition, the winds in the area, the size of the wind turbine, the depth of the harbours, material used etc.

The following are the different types:

- Barge

The floating platform has a large surface area in contact with the water, which is precisely what gives it stability. Like boats, they are made to move to avoid overstressing and stresses on the structure. To minimise these movements, the platform is usually fitted with heave plates, which are surfaces below the waterline.

2. Semi-Submergible

This design seeks to minimise the surface area exposed to the water, but always maximising the volume, which is what really displaces the mass of water and provides buoyancy. Geometrically, the ideal would be a sphere (maximum volume with the smallest surface area), but a sphere is not practical to manufacture, so the volumes that provide buoyancy are divided into several vertical cylinders (or parallelepipeds), which are joined by beams and braces to create a surface where the turbine can be installed. Their size and the distance between them determine their stability.

3. Spar

In this model, most of the weight is placed at the lowest possible point to provide stability. For example, if we throw a hollow, watertight cylinder into the water, it will float if the ratio of the height to the surface of the base is sufficient for the volume of water displaced to compensate for its weight. If the cylinder is homogeneous, it will not be stable floating vertically and will tip over to float horizontally. To avoid this, the cylinder is provided with a lot of mass at the end opposite to where the turbine is installed to maintain verticality.

4. Tensioned Legs Platform (TLP)

The newest and currently most technically risky concept: the platform does not actually float as such once the turbine is installed on it. The aim is to reduce the dimensions as much as possible in order to lower the manufacturing costs. The star geometry of three, four or five arms reduces the volumes of each arm to a minimum so that the platform floats without a load, i.e. without the wind turbine installed. Prior to installation, to prevent the assembly from turning over as the centre of gravity of the assembly rises, temporary, reusable floats are attached to the TLP platform, which in turn allows it to be towed to the offshore anchorage site. Once there, tensioned steel cables or tendons are connected and the temporary floats are disconnected for reuse on the next TLP platform to be installed.